Manufacturer of Nexalloy Premium Aluminum Welding Wire

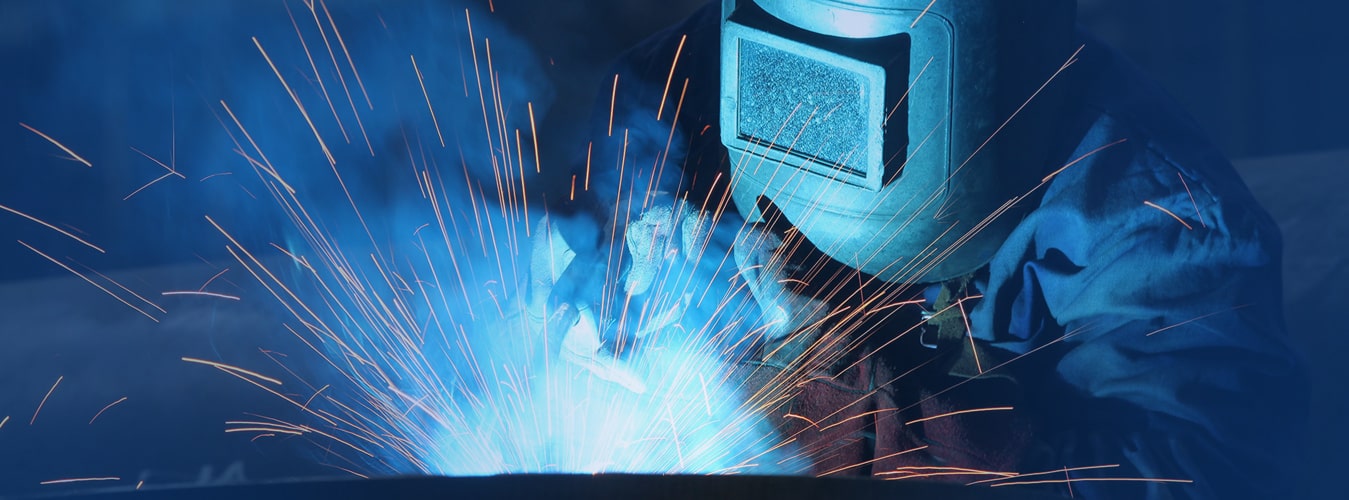

We deliver premium-quality aluminum welding consumables manufactured in our distinct in-house facility and backed by integrated technology, innovation, and specialized expertise. Our products are engineered to meet the demands of all critical welding applications, including marine, automotive, fabrication, and trailer manufacturing. We can help you optimize the process of welding aluminum and solve every challenge in the best possible way, thereby increasing productivity. Through decades of practical experience, we have developed industry-leading welding solutions, technical support, and customer service to ensure you get the best return on your investment.

Manufacturing a Greener Product in a Greener Environment

Nexal Aluminum considers environmental health and safety one of its topmost priorities and puts a high emphasis on implementing greener practices. Nexal was the first manufacturer to eliminate the use of added beryllium, a harmful additive. We are constantly looking for ways to improve our operations. Our manufacturing facilities and products meet or exceed all government requirements and standards.

Spools

TIG Rod

Drums

Improving Results in Your Aluminum Welding Application

Whether your business uses MIG or TIG welding, the fundamentals remain the same. Using the best practices for choosing equipment and consumables to weld aluminum saves time and money and ensures you get quality welds with the desired results. It also reduces the need for costly rework or overwelding. Choosing Nexalloy aluminum welding wire can make all the difference.

We follow stringent manufacturing measures to deliver excellence. With the following steps involved in our manufacturing process, we continue to innovate and improve results for our customers in aluminum welding:

Development

ProceduresProcess

ImprovementFailure

AnalysisMechanical

TestingResearch &

Development

Nexalloy Aluminum

Welding Wire

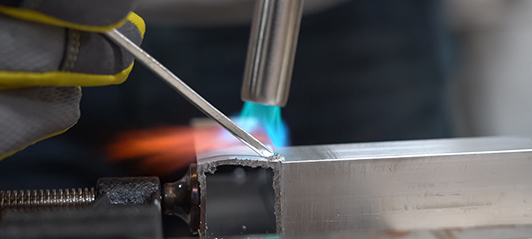

We specialize in manufacturing and supplying high-grade aluminum welding wire. Under the supervision of our expert engineers, each foot of wire is precisely manufactured using ultra-modern technology, supreme-quality raw materials, and innovative design. In addition, our aluminum wire offers benefits including:

- Low porosity weldments

- High feedability

- Diameter control

- Maximum consistency

World-Class Customer Experience

Aluminum welding experts at Nexal are available to provide you with the assistance you need in achieving best-in-class welds. Our team of metallurgical experts and engineering professionals work in state-of-the-art facilities to innovate and create solutions that optimize your welds in your specific application.

Aluminum Welding Wire Specialist

We solely specialize in manufacturing aluminum welding consumables. This enables us to provide unique welding solutions specific to the aluminum industry. Our experienced engineers and technicians understand industry-specific challenges and have the expertise to offer customized services. You can consult our industry-leading specialists to solve simple to complex issues.

Unmatched Quality

We are one of the leading manufacturers of aluminum welding wire in North America. We offer a wide range of aluminum wire and rods with unmatched quality. Through intensive research and development, we have developed a special finishing technique that allows the production of an aluminum wire with an extra clean surface. Keeping the entire weld assembly clean is crucial as aluminum is susceptible to contamination and oxidation, which can lead to undesirable results.

Design & Testing

Before our product reaches you, it undergoes rigorous testing for quality, safety, accuracy, and efficiency. We control every aspect of the manufacturing process within our facilities, from factory equipment, testing, and packaging to distribution. Every step in the process is monitored diligently to ensure complete customer satisfaction. We continue to implement better quality control procedures to maintain reliability and increase trust on the side of customers.